EVOLUTION Q8

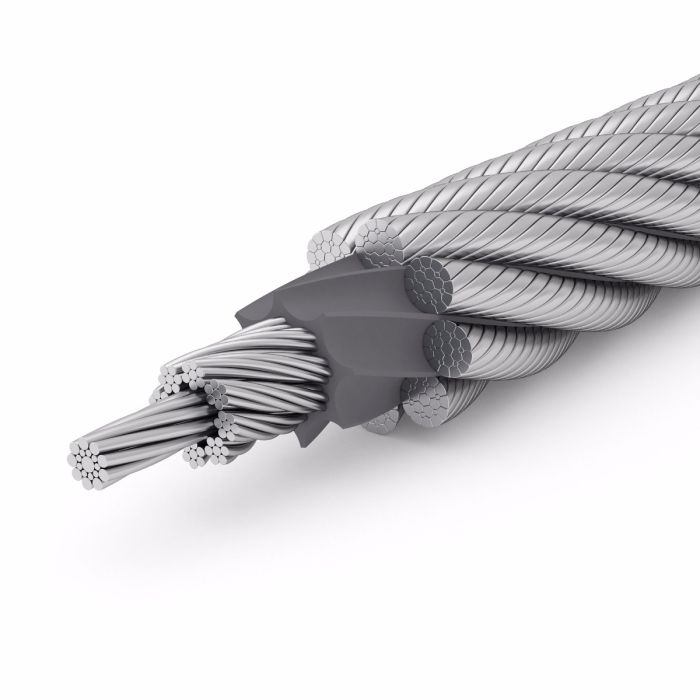

Superior longevity and high minimum breaking forces is what sets this rope apart. This is achieved thanks to SUPERFILL® and PLASTFILL®. Evolution Q8 works longer!

Specifications

Ordinary lay or lang’s lay, right or left lay

8 x K25F-EPIWRC, RCN 06

Use without swivel

✔ SUPERFILL®

✔ PLASTFILL®

The continuous operation of indoor and slab cranes in steel mills around the globe makes using high performance steel wire ropes offering you the maximum in service life and high operational safety a must. This helps steel mill operators keep downtimes under control and to a minimum. Evolution Q8 combines phenomenal longevity, ensured by a rope design developed specifically with a view to providing top performance under reverse bending cycles with high operator safety thanks to the reliable visibility of its discard criteria from the outside. Used on request, the special Pro Active lubrication with extreme heat-resistant grease provides permanent lubrication even in high temperature environments, thus ensuring exceptional longevity.

Benefits of EVOLUTION Q8:

- Outstanding longevity and highest profitability due to the excellent fatigue strength under reversed bending stresses of this flexible, yet robust rope construction

- Reliability and safety in use thanks to the high breaking forces achieved with SUPERFILL® compaction technology

- Trouble-free operation even under vibrations and shock loads thanks to the good absorption of dynamic loads

- Highest resistance to internal corrosion, even in the case of high operating temperatures, due to the use of galvanized high quality wires and the permanent lubrication of the rope core provided by the PLASTFILL® insert

- The high flexibility of the rope construction results in excellent longevity, particularly in the case of single-layer spooling systems

| Diameter | Weight | Minimum breaking force | |||||

|---|---|---|---|---|---|---|---|

| 1770 N/mm² | 1960 N/mm² | ||||||

| [mm] | [inch] | [kg/m] | [lbs/ft] | [kN] | [lbf] | [kN] | [lbf] |

| 12 | 0.64 | 0.43 | 110 | 24 729 | 122 | 27 427 | |

| 14 | 9/16 | 0.85 | 0.57 | 150 | 33 721 | 166 | 37 318 |

| 16 | 5/8 | 1.13 | 0.76 | 196 | 44 063 | 217 | 48 784 |

| 18 | 1.40 | 0.94 | 247 | 55 528 | 274 | 61 598 | |

| 20 | 1.78 | 1.19 | 306 | 68 792 | 339 | 76 210 | |

| 22 | 7/8 | 2.11 | 1.42 | 370 | 83 179 | 410 | 92 172 |

| 24 | 2.49 | 1.67 | 441 | 99 141 | 502 | 112 854 | |

| 25 | 1.00 | 2.74 | 1.84 | 478 | 107 459 | 529 | 118 924 |

| 26 | 2.94 | 1.98 | 517 | 116 226 | 572 | 128 591 | |

| 28 | 3.51 | 2.35 | 600 | 134 885 | 664 | 149 273 | |

| 29 | 3.72 | 2.50 | 643 | 144 552 | 712 | 160 064 | |

| 30 | 3.94 | 2.65 | 688 | 154 669 | 762 | 171 304 | |

| 32 | 1 1/4 | 4.65 | 3.12 | 783 | 176 025 | 867 | 194 909 |

| 34 | 5.24 | 3.52 | 882 | 198 281 | 977 | 219 638 | |

| 36 | 6.02 | 4.04 | 999 | 224 584 | 1 097 | 246 615 | |

| 38 | 1 1/2 | 6.69 | 4.49 | 1 104 | 248 189 | 1 223 | 274 941 |

| 40 | 7.41 | 4.97 | 1 223 | 274 941 | 1 355 | 304 616 | |

| 42 | 8.17 | 5.48 | 1 349 | 303 267 | 1 494 | 335 865 | |

| 44 | 1 3/4 | 9 | 6.04 | 1 480 | 332 717 | 1 639 | 368 462 |

| 46 | 9.80 | 6.58 | 1 618 | 363 741 | 1 792 | 402 858 | |

| 48 | 10.55 | 7.08 | 1 762 | 396 113 | 1 951 | 438 602 | |

| 50 | 2 | 11.44 | 7.68 | 1 912 | 429 835 | 2 117 | 475 921 |

| 52 | 12.40 | 8.32 | 2 067 | 464 680 | 2 289 | 514 588 | |

| 54 | 2 1/8 | 13.41 | 9 | 2 230 | 501 324 | 2 469 | 555 053 |