Anchor Lines

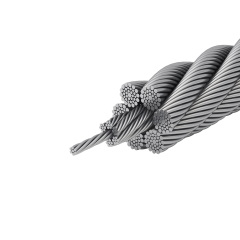

Teufelberger-Redaelli hi-tech steel wire ropes for Anchoring and Mooring applications on drilling rigs, semi-submersible vessels, FPSOs, etc., have been designed and manufactured to comply with the most severe requirements. Our family of hi-tech steel wire ropes for anchoring and mooring represent the evolution of conventional steel wire ropes which have been used for decades in a wide range of vessels and barges in the Offshore Oil&Gas industry. Compacted strands and high-grade carbon steel have been extensively used to improve the wire rope performances, in terms of load capacity and service lifetime.

Our six strand non compacted and compacted steel wire ropes offer top level performance for all anchoring applications, meanwhile our spiral strand HP and XF series represent the optimum solution for mooring applications where a long service lifetime is required. Teufelberger-Redaelli owns the control of the complete production process, starting from the wire rod purchase, through the wire drawing, stranding, closing and down to the final testing. Teufelberger-Redaelli provides worldwide after sales and technical services, such as rope installation & commissioning, inspection and refurbishing, whenever and wherever required. An experienced team, together with international Teufelberger-Redaelli partners, is available on demand around the clock.

After sales services and technical assistance have the highest priority among what Teufelberger-Redaelli has to offer.

The table below shows the rope type and recommended corrosion protection to achieve a given lifetime.

It contains general indications based on the current technical industry standards and should be considered as a support for the selection of the most suitable rope type and corrosion protection. These general indications are not intended as mandatory or stringent rules.

Corrosion depends on a wide variety of circumstances, such as environmental conditions, including water Salinity, temperature, flow speed, etc. and physical characteristics of the coating and the material to be protected against corrosion.

|

Required service lifetime |

Rope type |

Recommended corrosion protection |

|

< 5 years |

Stranded rope |

Class B(*) zinc coating |

|

<10 years |

Stranded rope |

Class B(*) zinc coating |

|

< 15 years |

Stranded rope |

Class A(*) zinc coating with sacrificial anodic zinc wires |

(*) As per EN 10264 or API 9A

For longer lifetime requirements we recommend you to take a look at our mooring lines section.

Teufelberger-Redaelli is also able to provide the necessary rope accessories such as standard or nonstandard anchor and mooring sockets, bending stiffness, shackles, etc.