HyperTEN

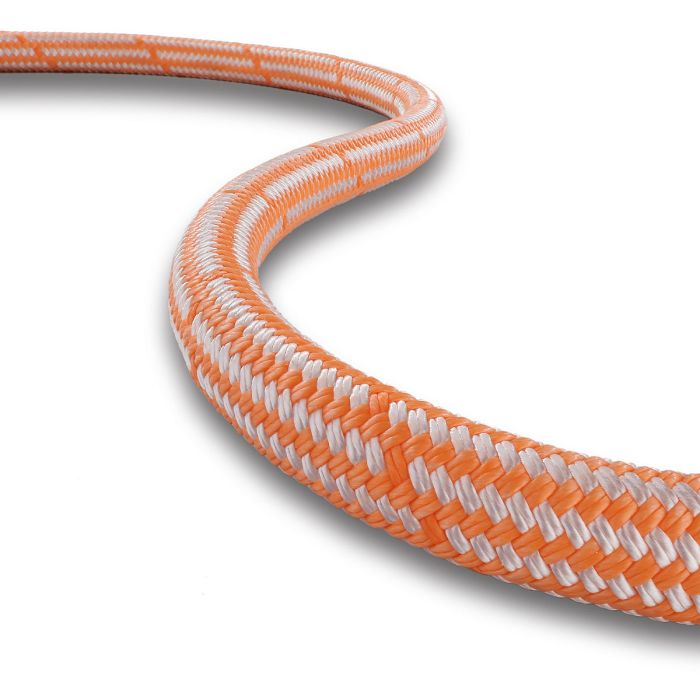

HyperTEN is our thermally pre-stretched high end fiber rope for highest technical requirements and is ideally suited as a replacement for steel wire ropes.

Specifications

Diameter: 3-34 mm

STS - Stronger Than Steel® technology

Cover: optionally with PES (HyperTEN-Pro P) or UHMWPE (HyperTEN-pro U)

Core: UHMWPE, thermally pre-stretched

Colors:

- Cover: various colors and/or color combinations possible

- Core: silver gray

Certification possible for the lifting of loads acc. to the Machinery Directive 2006/42/EC as amended

HyperTEN is a stable high strength fiber rope featuring extremely low stretch. It consists of UHMWPE fibers and can be fabricated either with a PES cover or a UHMWPE cover, depending on the application.

An optimized rope design combined with thermal stretching guarantees a perfect utilization of the available fiber characteristics as well as a closed rope structure that is extremely compact and stable.

Supreme breaking forces exceeding those of a steel wire rope with corresponding abrasion resistance usually permit a one to one substitution at the same diameter (incl. protective cover!) without the need for converting or adapting the periphery - at only 1/7 of the weight.

Of course, HyperTEN will be specifically adapted to your application. Customized rope end terminations such as

- Splice with or without plastic, steel, stainless steel or tubular thimble

- End bond,

- Stitching,

- Swaging,

- Tapered end, and

- [Slaice]®

are the perfect link between the rope and your attachment point.

The benefits of HyperTEN are:

- 1/7 of the weight of comparable steel wire ropes

- Extremely high breaking force - higher than that of most steel wire ropes of the same diameter available in the market

- No corrosion and/or soiling caused by rope grease

- No danger of injury, easy and quick handling

- Flexible design

- Supreme abrasion resistance due to a smooth surface, especially when provided with a cover

- Very high bending fatigue strength and extremely long service life

- The kinetic energy released on rope damage is considerably lower than in case of steel wire ropes.

- Very low initial and working stretch (already eliminated during production)

Our fiber rope HyperTEN is used for various technical applications. It is especially suitable when used as

- Fiber rope for agricultural equipment

- Winch launching rope for gliders

- Fiber rope for drum winches

- Fiber rope for spill winches

- Fiber rope for many other technical applications

| Kern ∅ / Seil ∅ ohne Mantel [mm] | Seil ∅ mit Mantel [mm] | Gewicht HyperTEN / HyperTEN+ [g/m] | Gewicht HyperTEN Pro-P / HyperTEN + Pro-P [g/m] | Gewicht HyperTEN Pro-U / HyperTEN + Pro-U [g/m] | MBK*** [kN] | |

|---|---|---|---|---|---|---|

| 3 | 5 | 7 | 15 | 12 | 13 | |

| 4 | 6 | 12 | 22 | 19 | 23 | |

| 5 | 7 | 20 | 47 | 39 | 40 | |

| 6 | 8 | 25 | 53 | 44 | 48 | |

| 7 | 9 | 36 | 69 | 60 | 70 | |

| 8 | 10 | 47 | 84 | 73 | 90 | |

| 9 | 11 | 59 | 100 | 88 | 105 | |

| 10 | 12 | 65 | 105 | 94 | 120 | |

| 11 | 13 | 73 | 114 | 102 | 145 | |

| 12 | 15 | 101 | 171 | 150 | 180 | |

| 14 | 17 | 130 | 217 | 192 | 235 | |

| 15 | 18 | 146 | 237 | 210 | 270 | |

| 16 | 20 | 176 | 293 | 259 | 300 | |

| 18 | 23 | 215 | 381 | 332 | 355 | |

| 20 | 25 | 253 | 454 | 395 | 440 | |

| 22 | 28 | 270 | 507 | 437 | 500 | |

| 24 | 30 | 350 | 629 | 547 | 600 | |

| 26 | 32 | 366 | 650 | 568 | 650 | |

| 28 | 34 | 425 | 710 | 627 | 700 | |

| 30 | 36 | 488 | 792 | 703 | 800 | |

| 32 | 39 | 555 | 936 | 824 | 900 | |

| 34 | 41 | 626 | 1 028 | 910 | 1 010 |