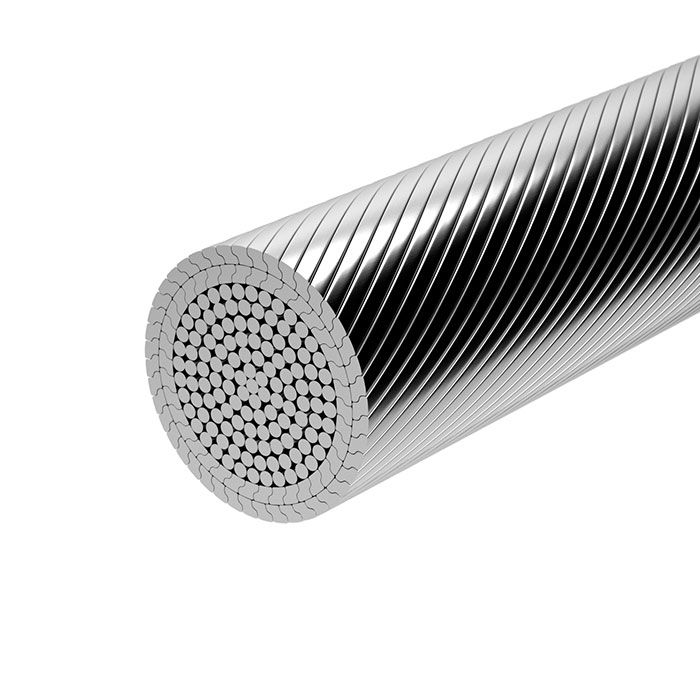

STAINLESS STEEL FULL LOCKED COIL ROPES (FLX)

FLX ropes are manufactured using outer layers interlocking Z-shaped stainless-steel wires around a core of stainless-steel round wires. The standard stainless-steel grade used to produce FLX is 1.4401 (AISI 316). Each wire has a minimum tensile strength of 1470 N/mm2. Stainless steel cables do not need for an internal corrosion inhibitor compound. Therefore, they are usually produced dry or with a light manufacturing oil.

Specifications

- Excellent axial stiffness

- Optimum strength to weight ratio

- Excellent fatigue resistance

- Torque balanced

- Suitable for cable clamping.

- Teufelberger-Redaelli patented anti-vibration solution (Surface Treatment)

Teufelberger-Redaelli Stainless Steel Full Locked Coil (FLX) ropes are manufactured using outer layers interlocking Z-shaped stainless-steel wires around a core of stainless-steel round wires.

The outer layers of Z-shaped wires are generally spun in opposite directions around a central core of round wires. Each individual wire is tested and verified for tensile strength, ductility, elongation at fracture, bending and torsional properties in accordance with EN 10264. Main properties: excellent axial stiffness, optimum strength to weight ratio, excellent fatigue resistance, torque balanced, excellent resistance to lateral forces meaning most suitable for cable clamping.

Mechanical characteristics of steel wires:

- Nominal Tensile Strength 1450 Mpa (after hot dip galvanizing)

- Proof Stress Rp 0.2 1080 Mpa

- Modulus of Elasticity 130 ± 10kN/mm²

Facades, Cable net roofs and canopies, Cable Stayed bridges, Hangers of Arch bridges, Hangers and main cable of suspension bridges.