Technologies

SOLITEC® technology

The SOLITEC® rope generation has been developed by TEUFELBERGER to offer our customers durable and highly flexible ropes. The sophisticated rope design of SOLITEC® steel wire ropes is based on a special manufacturing process. With this process, our technicians managed to exactly determine the initial elongation of the rope already in a very early phase of production, thus largely forestalling it.

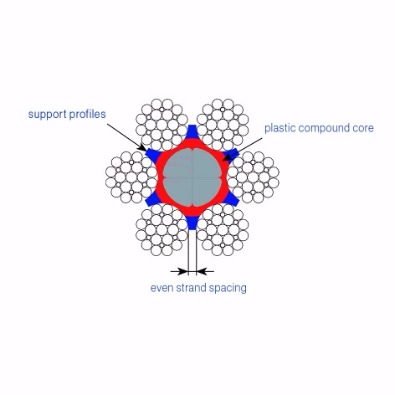

SOLITEC® ropes from TEUFELBERGER are characterized by a plastic compound insert and support profiles resulting in major advantages.

The plastic compound insert

SOLITEC® ropes are provided with a braided and greased fiber core covered in a compact synthetic coat, which provides for a perfect roundness of the insert while ensuring supreme resistance to tensile forces. Therefore, the SOLITEC® insert cannot tear or break. Moreover, the cold strands are pressed into the plastic insert during the stranding process.

The support profiles

TEUFELBERGER is the only manufacturer providing its SOLITEC® steel wire ropes with preformed support profiles between the strands. This creates a perfectly even distribution of the strands in the rope and prevents the strands from touching one another. Thus, the consequences of such contact between the strands, like corrosion and wire breakage, are permanently avoided.

Vibration-dampening plastic support strands are used across the entire splicing zone. Thus the perfect and consistent quality without any weak spots is ensured over the whole length. In addition, the support profiles slide easily on top of the surface of the plastic compound core, which helps to increase the service life of the rope.

The precise dimensioning of the trapezoidal support profiles helps achieve as high a level of product consistency as possible. The profiles fully fill the spaces between the strands. This ensures low-vibration running characteristics and minimized noise. Furthermore, the annoying “settling” of the rope while leaving it to hang or letting it run in unloaded (empty) state is a thing of the past. Most of the initial elongation is already forestalled in the production process. However, a slight elongation of the rope that is required for the operator, e.g. for splice regeneration, will be available throughout the service life of the rope.

The technology of the SOLITEC® steel wire rope offers you the following advantages:

- Excellent longevity

- Very low elongation

- Perfectly round rope geometry

- Symmetrical strand distribution and permanent prevention of contact between the strands

- Breakproof plastic compound core

- Permanently greased fiber core without leakage of grease

- High elasticity and flexibility

- High dimensional stability under lateral pressure

- Full splicing compatibility with Lo-Stretch® ropes

Wide range of applications

Our SOLITEC® ropes are suited for use in ropeway systems as well as in the field of underground mining. They can be used as hauling/carrying rope, as hauling/hoist rope and as drive rope.

STRESSLESS technology

The STRESSLESS technology developed by TEUFELBERGER is based on the sliding guide process, a method tried and tested over several decades, especially as an ideal technique for wire preforming.

Functioning

In the sliding guide process applied during closing, the profiled wires are guided to the closing point by means of a method that is particularly gentle on the surface. The profiled wires used are manufactured especially for TEUFELBERGER and procured only from premium wire suppliers in the EU.

The trick in the sliding guide process is to bring the wires into exactly the helical shape that corresponds with the respective rope diameter. The helical-shaped wires provide, among others, for a neutral behavior when handling (e.g. pulling) the rope. Moreover, this construction fixes the outer wire layers in the rope structure so they cannot pop out in case of damage.

Therefore, our STRESSLESS technology results in a particularly low-twist construction and production, which, first and foremost, substantially facilitates the installation of the ropes.

STRESSLESS DATA – the carrying rope technology that can do more

Our revolutionary STRESSLESS DATA technology integrates fiber optic bundles securely into the carrying rope. Operators of passenger ropeways, material ropeways or cable crane facilities benefit from the simple and well protected installation of data lines right inside the rope. Moreover, electric conductors can be integrated in the carrying rope to provide top terminals with power.

STRESSLESS DATA offers you the following benefits:

- Highest data security

- Reduced investment costs

- No maintenance costs

Applications of our STRESSLESS technology

Our high performance steel wire ropes featuring the STRESSLESS technology are used as carrying ropes in passenger ropeways and material handling systems. This carrying rope is also available with integrated optical fibers or electric conductor.