...my rope is affected by UV?

One of the main questions in the rope world is “Is my rope still good to work with?” Manufacturers specify a theoretical service life in their instructions for use. This is mainly based on very rare use. The actual service life, especially when the rope is heavily used, depends on a lot of factors that are beyond the control of manufacturers. In this series, TEUFELBERGER presents the results of a study made on “Deliberate damage of ropes”. In this article, we answer some frequent questions on the effect of UV radiation on ropes and share the results about the topic of “UV Resistance” with you.

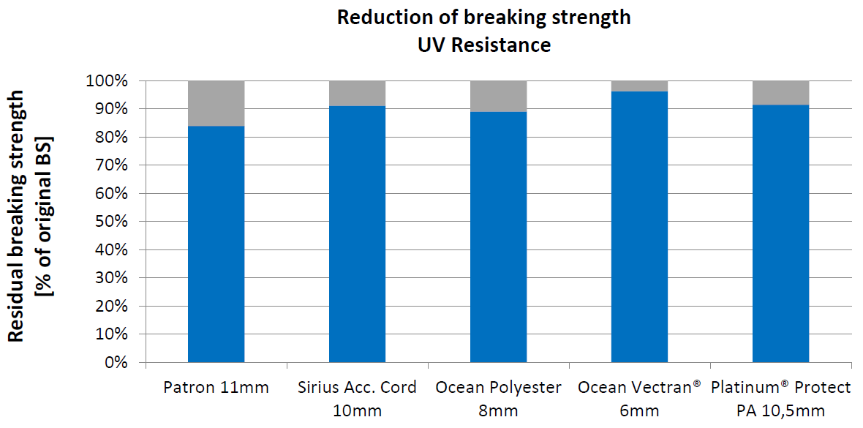

For testing the resistance to UV (Ultraviolet) light of the rope samples, a cooperation with theAustrian Research Institute (OFI) was conducted. The rope samples tested were exposed toweathering in accelerated laboratory tests with rain/dry periods and periods of light/darknessfor approximately 2000 hours. This corresponds to about 2-3 years of use in the middleEuropean climate. After the weathering, the ropes were brought back to TEUFELBERGERand were tested for their residual strength.

The following ropes were tested:

- Patron 11 white-red (Polyamide)

- Sirius Accessory Cord 10mm (Polyester)

- Ocean Polyester 8mm (Polyester core / Polyester-Aramid cover)

- Ocean Vectran® 6mm (Vectran® core / Polyester-Aramid cover)

- Platinum® Protect PA 10,5mm (Polyamide)

Some ropes showed changes in color and handling after the weathering, while other ropesshowed no visual changes. Visible signs of UV deterioration can be:

- Stiffening

- Yellowing

- Fraying/Roughening

- Discoloration or fading of colors

Pic.1: Patron 11mm – original

Pic.2: Patron 11mm – after weathering

Pic.3: Sirius Acc. Cord 10mm – original

Pic.4: Sirius Acc. Cord 10mm – after weathering

The results show, that UV radiation caused by regular outdoor use influences the breaking strength of ropes. The reduction in breaking strength was predominately with Polyamide ropes. There was also an increase in elongation and the ropes were stiffer to handle after the UV exposure. When tested under load, some of the ropes’ covers started to fray which implies that the fibers were damaged by the UV radiation and thus broke more frequently under load.

Conclusion & Recommendation

- The results prove that there is no way for the user to determine the discard criteria only by the rope’s visual appearance. Even ropes that are not visibly damaged can have greatly reduced breaking forces.

- It can be assumed that ropes that show strong signs of UV exposure (yellowing, stiffening or roughened coat) also show a strong decrease in breaking load. Therefore, these ropes must be retired!

- Based on the material properties and the tests, it has been shown that polyester ropes are less susceptible to a reduction in the breaking load due to UV radiation than polyamide ropes.