...my rope gets in contact with dirt?

One of the main questions in the rope world is “Is my rope still good to work with?” Manufacturers specify a theoretical service life in their instructions for use. This is mainly based on very rare use. The actual service life, especially when the rope is heavily used, depends on a lot of factors that are beyond the control of manufacturers. In this series, TEUFELBERGER presents the results of a study made on “Deliberate damage of ropes”. In this article, we answer some frequent questions on the impact that dirt has on the strength of the ropes.

1. Standard Dirt

In these tests, a mix of 3 liter water and 1.3kg standardized dirt according to DIN ISO 9462-2007 (loam, mud, sand, gravel) were used. The rope samples were submerged in the dirt-water-mix, the dirt was rubbed onto the samples and then samples were pulled over pulleys for 10 times to fix the dirt and simulate application.

Pic.1: Treatment of samples with standard dirt

Pic.2: Braided Safety Blue 12.7 mm before and after treatment

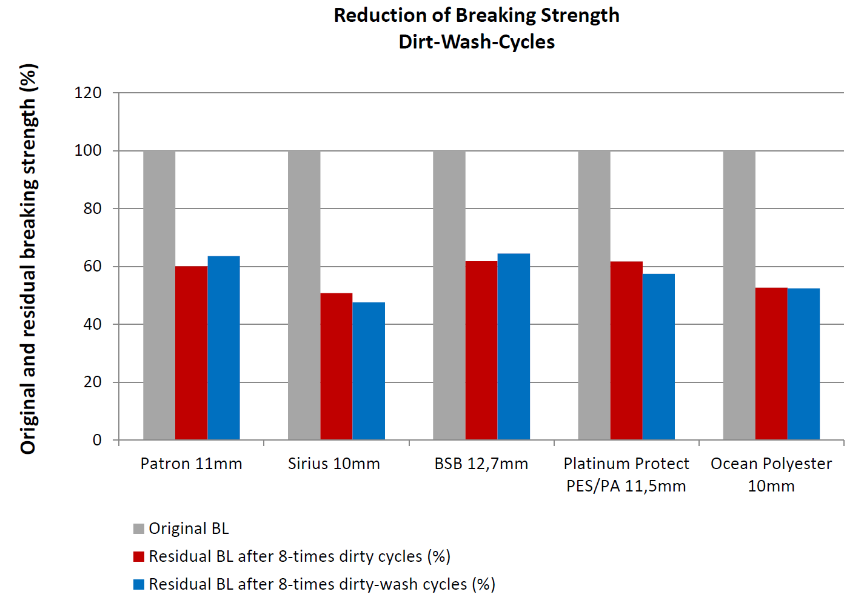

Then the test samples were divided into two groups. For sampling group 1, the dirt-dry-procedure was repeated for eight times. After the final cycle the ropes were tested for their residual breaking strength. The ropes of sampling group 2 were washed with 30°C, Scrubba rope cleaner and no spinning after each dirt-cycle and left to dry naturally. After the final cycle, the ropes were also tested for their residual breaking strength.

The following ropes were tested in each sampling group:

- Patron 11 mm (Polyamide core / Polyamide cover)

- Sirius 10 mm (Polyester core / Polyester cover)

- Braided Safety Blue (BSB) 12.7mm (Polyamide core / Polyester cover)

- Platinum PES/PA 11.5mm (Polyamide core / Polyester cover)

- Ocean polyester 10mm (Polyester core / Polyester-Aramid cover)

The tests show, that dirt harms the rope significantly. The loss of breaking strength was at around 40% to 50% on all rope samples. This implies that the dirt enters inside the rope and damages the load bearing core from the inside. The degree of damage is not visible from the outside. Fine grained dirt like sand should therefore be avoided if possible.

The tests also show that washing can’t „repair“ the rope as soon as dirt enters into the core. Even after washing with a rope detergent, the harming dirt remained in the core and caused damage.

Conclusion & Recommendation

- Dirt harms the rope significantly, breaking strength is reduced by about 40% Salt or resin damage the rope to a certain extent.

- Damages are not always visible from the outside, please keep that in mind!

- Washing can’t repair or fix the rope once dirt entered into the core.

- Avoid dirt, salt or tree sap as much as possible.

- If the rope shows visible damage or the properties of the ropes are impacted by dirt, retire the rope immediately!