How to choose the right tree climbing rope ?

- by John Trenchard

When I started climbing rope selection was easy, there was one choice, it was a multi plait rope which was one color and simple to splice with basic tools. It got the job done but it was very inefficient and hard work. Nowadays climbers have a massive range to choose from with fancy names, cool colors and some very clever technology in their construction to make tree work that bit easier.

But with so many choices it gets difficult to make sure that you have chosen the best rope for any given application, it depends on many things such as climbing techniques, type of work you do, down to the equipment you are going to use on it to climb.

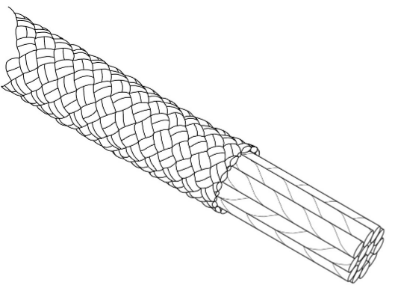

Moving forward from my first multi plait rope, modern ropes in their construction are described as ‘Kernmantle’. Kern meaning core and mantle meaning sheath or cover, so the ropes we use today have a cover and a core which share the load in different ways depending on their application and construction. Understanding the different types will help climbers make an informed decision on what is the best rope for them.

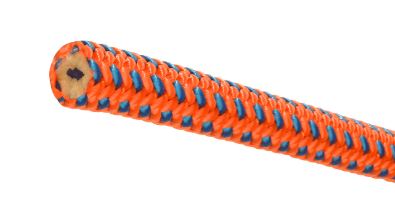

16 strand rope - Braided Safety Blue

Let’s start with a 12.7mm 16 strand rope. Braided Safety Blue has a cover made up of 16 braided strands, it has a woven core which incorporates blue yarns, these are there as a visual warning to indicate the rope is dangerously damaged if these are visible. Most of the strength of the rope is in the outer sheath, the core yarns are there to prevent the rope from flattening when it is pulled over branches. Being made up of 16 large strands it provides very good grip which is particularly beneficial to climbers who are using traditional body thrusting techniques. It’s size and feel help to avoid hand and arm fatigue when climbing.

As climbing techniques have evolved climbers have started to use different types of friction hitches and incorporate pulleys in their systems to advance the rope or take slack in with one hand and also to place pulleys at the tie-in point to reduce friction.

With the addition of simple devices such as foot ascenders, this makes the climb easier with less strain on the arms and shoulders but to achieve this climbers needed a different type of rope that was firm and flexible but has less bounce.

24 strand rope - Tachyon & Fly

This led to the development of double braided ropes with a tighter braided cover and a woven core, both of which share the load equally.

Tachyon was one of the first ropes developed for arborists with a 24-strand cover and a woven core providing strength and stability, Tachyon actually has an additional inner core to help keep the diameter consistent in a loaded state which suited friction hitches.

Double braided ropes in their construction have continued to evolve with climbing techniques to help provide climbers with the correct rope depending on their needs.

By changing the core for example, as in Fly, from a woven core to parallel fibers you have a rope that is very tactile in your hands but has low elongation with minimal bounce, this benefits climbers using stationary rope techniques.

With the need for ropes to cope with mechanical devices including foot and knee ascenders with toothed cams for SRT climbing, ropes have been developed with a tight braided cover.

32 strand rope - Xstatic & drenaLINE

Xstatic and drenaLINE for example have a 32-strand cover and a parallel core to cope with the demands of mechanical devices, Xstatic has been developed with stiff characteristics suited to SRT, whilst drenaLINE is more supple and aimed at the climber which employs both moving rope and stationary rope methods in their climbing.

There are also climbers who prefer to access the tree with a devoted accessline, climb the line with cammed devices and then switch to another to work the tree down.

The benefit of these types of access lines is that they are very low stretch which makes ascent very efficient with low energy leaks but they are not always the best to work from, that’s why they switch.

Certification, elongation, application

The problem for a climber when choosing a rope is that they often all fall into the same category of testing 1891 type A/ANSI Z133-2012, but it’s important to remember how you need your climbing rope to perform. Most climbing ropes are designed with a small amount of elongation, although this can be slightly frustrating during a long ascent it is crucial in protecting a climber and their anchor point should a fall happen in the tree. Some ropes, such as Tachyon, actually have a high stretch capability at high loads designed to minimize the shock effect on a climber in the event of a fall.

With that in mind be careful working from low stretch ropes.

Even with elongation climbing lines are classed as static. They are designed to hold a static load (the climber) underan anchor point, they are not designed to cope with dynamic (falling) loading similar as what you find in a rigging scenario. The difference between rigging ropes and climbing ropes is that a rigging rope is designed to deal with dynamic loading in its construction and choice of materials, a climbing rope is not.

If a climbing line has been exposed to sudden strains or shock loading this may result in rope failure and the rope should be retired as PPE

Ropes inspection and handling

All climbing ropes should be inspected before use looking for cuts, glazing (heat damage) contamination, abrasions, stiffness, and diameter change. If there is any doubt about its safety, it should be referred back to the manufacturer or a competent person for inspection.Ropes have a shelf life of 10 years but have a working life limited to 5 years, always check with the manufacturer. Ropes must be retired sooner if defects are noticed.

Sand and dirt can cause severe damage to a rope by cutting the core of climbing lines, it’s best to store ropes in a rope bag or bucket, if they get wet then allow them to dry at room temperature.

If they are really dirty they can be washed, wohever do not wash them in normal washing powder as some types may weaken the rope by 50%, Teufelberger has its own brand of rope-friendly detergent or just wash the rope in water with a temperature of no more than 30° Celsius.

My advice to a colleague in respect to rope selection would be:

• Chose a rope compatible with your climbing style

• Buy a bright color

• Use a rope bag

• Choose a rope with good end-user information, i.e. age, traceability, length, diameter.

In a climbing bag, I would recommend having 2 ropes, one suited to double rope and one for SRT. The best choice is to choose ropes that can do both, I use a 35m Fly and a 45m drenaLINE.

Who is John Trenchard?

• Registered Instructor and Assessor for NPTC chainsaw qualifications.

• Lecturing at Bicton College

• Lantra Vérifier

• Head judge at UK Chapter Competitions.

-

Braided Safety Blue

The Braided Safety Blue from TEUFELBERGER combines features that ensure unparalleled safety, ergonomics and durability during climbing. -

Fly

The Fly climbing rope features a well-balanced kernmantle design and excels due to its brilliant handling features. -

Tachyon

Thanks to its unparalleled feel and its exceptional performance, Tachyon is ideal for use with the latest mechanical systems. -

Xstatic

Straight to the point! With Xstatic 11.7 TEUFELBERGER designed a perfectly static rope specifically for Single Rope Technique (SRT) climbing. -

drenaLINE

One rope equally efficient! Our drenaLINE gives ultimate freedom to the climber to choose the right technique for the task.