...chemicals touch my rope?

One of the main questions in the rope world is “Is my rope still good to work with?” Manufacturers specify a theoretical service life in their instructions for use. This is mainly based on very rare use. The actual service life, especially when the rope is heavily used, depends on a lot of factors that are beyond the control of manufacturers. In this series, TEUFELBERGER presents the results of a study made on “Deliberate damage of ropes”. In this article, we answer some frequent questions on the influence of different chemicals like battery acid on ropes and share the results about the topic of “Chemical resistance”.

For these tests, the rope samples were brought in contact with different chemicals. After the application, the samples were allowed to dry naturally for 24 hours and were then tested for their residual strength.

The following chemicals were tested:

- Gasoline

- Battery acid

- Corrosion protection paint

The following ropes were tested:

- Patron 11 white-red (Polyamide)

- Sirius Accessory Cord 10mm (Polyester)

- Ocean Polyester 8mm (Polyester core/ Polyester-Aramid cover)

- Ocean Vectran® 6mm (Vectran® core/ Polyester-Aramid cover)

- Platinum® Protect PES/PA 10.5mm (Polyamide core/ Polyester cover)

- Platinum® Protect PA 10.5mm (Polyamide)

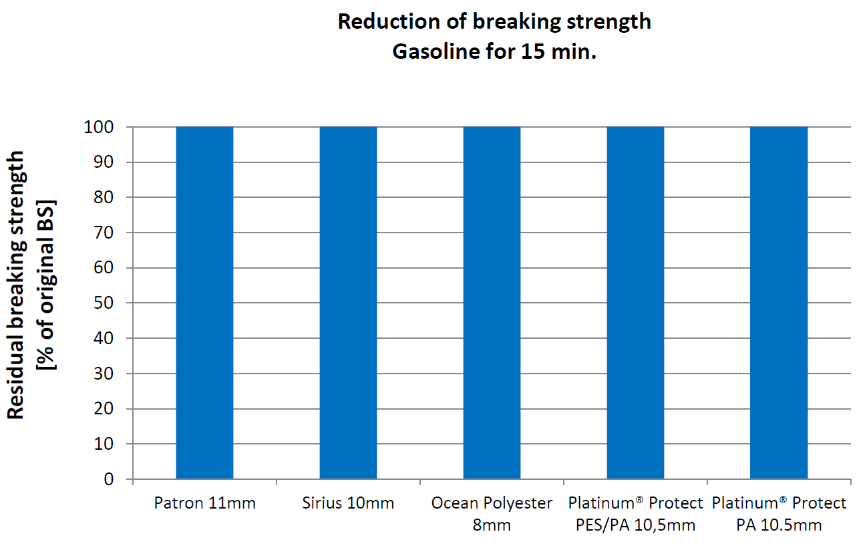

1. Gasoline

The rope samples were submerged into gasoline (white spirit / two-stroke) for 15 minutes. Then allowed to dry naturally and tested for their residual breaking strength. Neither visually, nor in the handling, was there any change to the rope detected. The results in the following graph indicate, that there were also no changes in breaking strength when tested for the residual strength.

Pic.1: Patron 11mm – after gasoline influence for 15 min

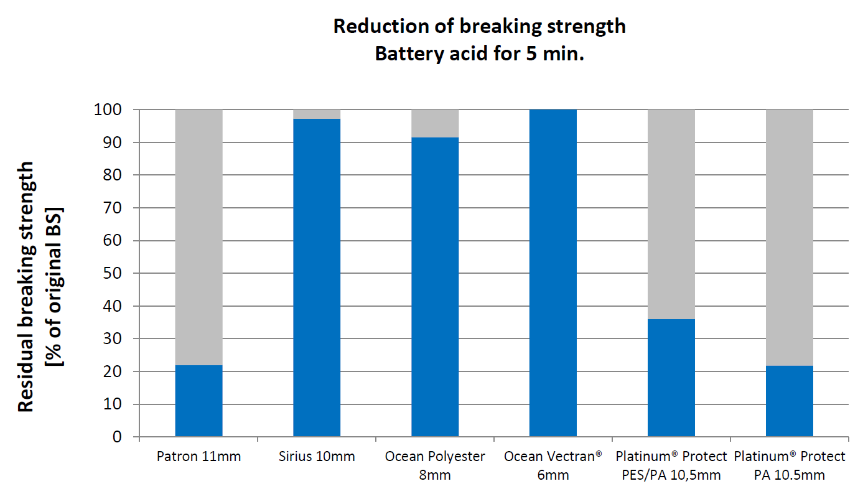

2. Battery acid

The rope samples were submerged into battery acid (w(H2SO4 = 37%)) for 5 minutes. Then allowed to dry naturally and tested for their residual breaking strength. It was noted that both a discoloration and degradation of the cover were visible. In addition particularly the ropes with Polyamide felt greasy and got stiffer with handling. The results in the following graph demonstrate, that there was significant reduction of breaking strength depending on the rope’s material. Ropes made of polyamide or with polyamide cores were particularly badly damaged by the battery acid.

Pic.2: Patron 11mm – after battery acid influence for 5 min

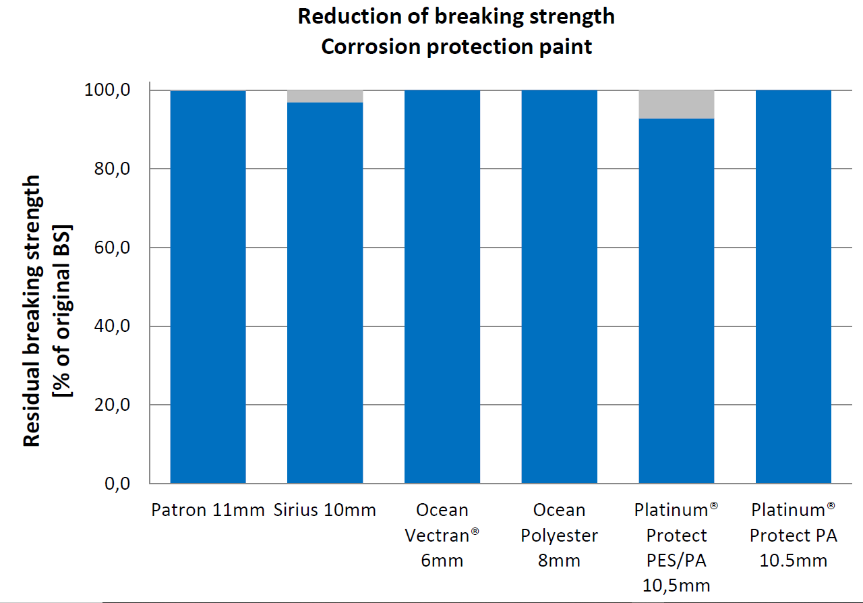

3. Corrosion protection paint

The rope samples were submerged for short time into corrosion protection paint. Excess paint was removed with a spatula. Then the samples were allowed to dry naturally before they were tested for their residual strength. The visual appearance of the samples changed as the whole sample was covered in paint. In the handling, all of the rope samples were a lot stiffer than before. Nevertheless, the graph shows that corrosion protection paint had no influence on the breaking strength of the ropes.

Pic.3: Patron 11mm – covered with corrosion protection paint

In a second series, tests were carried out to determine whether the coating could be removed with mineral spirits. Therefore Patron 11mm was submerged into cleaning benzine (white spirit). The rope felt more flexible again after storage in the solvent (1h), but the cleaning effect was poor and hardly any better even when using mechanical aids such as spatulas etc. In addition, a small reduction of breaking strength (4%) was observed. Cleaning with benzine is very expensive, not very effective and reduces the strength of the rope. It is not recommended.

Conclusion & Recommendation

- There was no change in breaking strength when ropes came in contact with gasoline or corrosion protection paint.

- There can be signification reduction in breaking strength when the ropes come in contact with battery acid. Please retire these ropes immediately!

- It is generally harmless to clean dirty ropes with gasoline. Observe the safety provisions for the use of white spirit and clean only if it is absolutely necessary!

- It is not recommended to clean ropes with benzine (Petroleum ether) as slight reduction of breaking strength can occur.

- Generally, keep your ropes away from chemicals!