Covid-19 (Corona Virus) Rope disinfection

1. Multiple desinfection of ropes

In early 2020, the Coronavirus situation surprised the world. In March, we presented the results of a previous study concerning the impact of disinfection on ropes. In this study, semi-static polyamide (i.e. Nylon) ropes were disinfected with a mix of Isopropyl (70%) and tested for their residual strength. This was a one-time test. No significant change in the ropes’ characteristics (diameter, weight, strength, elongation) occurred in these tests. Please find the results of the previous study below (2. One time desinfection of ropes).

This also coincides with the statements made by our fiber suppliers who confirm that, Polyamide fibers are satisfactory resistant to Isopropyl alcohol and disinfection of ropes based on mentioned chemical should not have any negative impact on the ropes.

Later in the year, in the interest of customer safety and as a result of new Covid-19 regulations, climbing gyms around the world were forced to disinfect ropes, holds and equipment at a far more frequent rate, some even after each climber. Gym owners began questioning the impact of all that disinfection on the performance of the ropes. Many of them reached out to us directly for the answer.

In order to answer this question, and to be able to give an official manufacturer’s recommendation concerning frequent disinfection of ropes and its impact on the ropes’ handling, we conducted a second, more specific study. We are ecstatic to be able to share with you the testing procedures and results of that study.

1.1 Test samples & procedure

Tested rope

- Dynamic climbing rope

- Chalkline 9.7mmPolyamide core / Polyamide cover

- Blue-grey

- 3 samples / 10m each

Disinfectant

- Isopropyl 70% (70% Isopropyl alcohol, 30% distilled water)

Testing procedure

- Simulation of climbing

Ten climb/lower simulations were performed by pulling the rope through a belay device (Petzl GriGri) bi-directionally (fig.1) - Disinfection of climbing rope

Rope samples were sprayed completely with Isopropyl 70% (distance approx. 30cm) and wiped down with a damp cotton cloth (also with Isopropyl 70%) (fig. 2/3) - Drying the rope

Rope sample was left to dry naturally for 30 Minutes

Fig.1

Fig.2

Fig.3

Sample 1:

60 climbing simulations and 6 disinfections (after each cycle of 10 climbing simulations) were executed during one day

Sample 2:

180 climb/lower simulations and 18 disinfections (after each cycle of 10 simulations) were executed each day during 3 days. The sample dried overnight.

1.2 Conclusion & Recommendation

The results of the study showed, that there is no significant difference in the tested values (impact force at first fall, dynamic elongation, total falls) or in handling characteristics between the new rope and the two disinfected rope samples. Based on these results and the statement of the fiber suppliers, from a manufacturer’s point of view it is acceptable to disinfect a rope multiple times following the instructions below:

- Dynamic climbing ropes (and other ropes made of Polyamide) can be disinfected by spraying them with a solution of 70% Isopropyl and 30% Distilled Water, wiping them down with a damp cloth (also with Isopropyl), then air drying them naturally away from a heat source or direct sunlight.

- The Safety rules provided on the safety data sheet should be followed for all other rope care

- A qualified inspection of the rope is mandatory.

- This data applies to the disinfection of the ropes only and does not make any recommendations as to any other procedures or policies for disinfecting gear, holds or other aspects of the gym.

- The data applies to the impact of the disinfection process on the rope itself, not on the actual effectiveness of the disinfection against the Coronavirus or any other potential infectious diseases.

2. One time desinfection of ropes

The Corona Virus and the Covid-19 disease caused by it are spreading all over the world and bring restrictions in all areas of life. The general recommendations include an avoidance of social contacts by self-quarantine and increased hand hygienic to slow down contagion. TEUFELBERGER supports this measures and asks partners and customers to do the same.

Nevertheless, we got some questions, if a disinfection of ropes might be sensible and possible in these times. As we already did some tests on this in the past, we want to share that information with you. But please keep in mind that disinfectants are scarce at the moment and are more urgently needed in other places than for the disinfection of ropes. #stayhome #staysafe

In 2015, TEUFELBERGER, the global rope manufacturer and parent company of MAXIM climbing ropes and ROBLINE marine ropes, conducted a study about “Deliberate Damage of Ropes”. In this study, we tested the impact of different kinds of soiling, washing and abrasion on the rope’s breaking strength. In the arborist business, for example, it is a normal course of business to disinfect the equipment after working in pest-infested regions. Therefore, as a part of the study, the impact of disinfection was also tested. In light of the recent developments with to the Corona Virus, we would like to recall these results and share them with you.

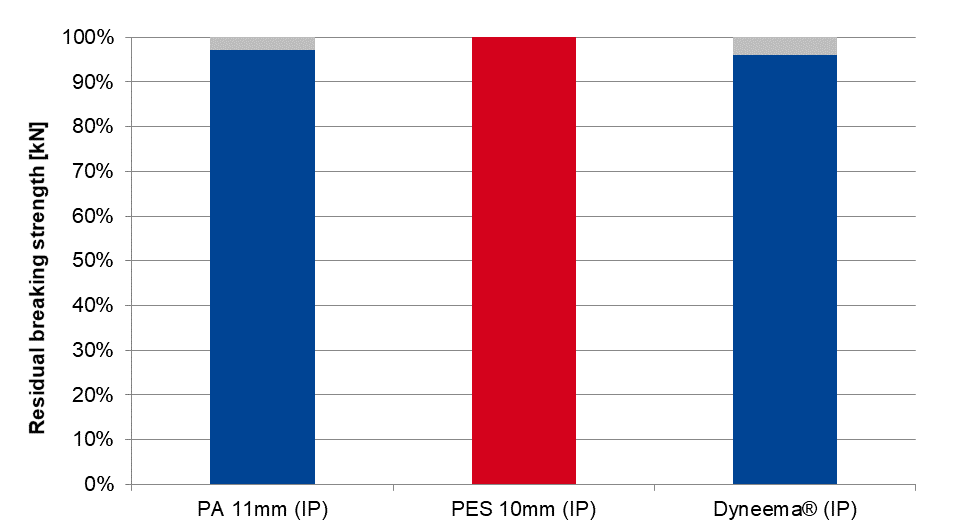

In the study we tested ropes made of different materials (Nylon, Polyester, Dyneema®). The ropes were disinfected one time by being submerged in a solution of 70% Isopropanol and 30% distilled water for 3 minutes and then left to air dry naturally for 48 hours before being tested for their residual strength.

The results show, that there has been no decrease in breaking strength for Polyester ropes, and only 2-4% decrease for other ropes tested. However, we did note that the hand and flexibility of the rope does deteriorate after the disinfection.

Based on these results, from TEUFELBERGER’s perspective, it is acceptable to disinfect your ropes in this manner.

We recommend the following when disinfection ropes:

- Ropes can be disinfected by being submerged in a solution of 70% Isopropanol and 30% Distilled Water for 3 minutes maximum.

- Air dry the ropes naturally away from heat source or direct sunlight

- The Safety rules provided on the safety data sheet should be followed for all other rope care

- Disinfection should be done when needed and not daily - the long term impact is being tested. A qualified inspection of the rope is mandatory.

This Data applies to the disinfection of the ropes themselves and does not make any recommendations as to any other procedures or policies for preventing infection in other areas.

Since the impact of Covid-19 is still being studied and further understood, this study represents a point in time test. We are continuing to test and will update this document as new data becomes available.