Dienste

Teufelberger-Redaelli verfügt über ein spezialisiertes Team von Technikern mit bautechnisches Fachwissen und das ruch eine umfangreiche Flotte von branchenführenden Installations- und Spanngeräten unterstützt wird.

Ob bei einem Neubau oder bei der Renovierung und Erneuerung eines bestehenden Bauwerks, unser engagiertes Techniker-Team steht zur Verfügung, um die Herausforderungen Ihres Projekts zu besprechen. Sie können Standard- und kundenspezifische Installations- und Spannlösungen anbieten, die den Bedingungen und Einschränkungen Ihres Bauvorhabens entsprechen.

Nach der Fertigstellung eines Bauwerks und dem Beginn der Nutzungsdauer der Seile ist es von entscheidender Bedeutung, dass diese regelmäßig inspiziert und gewartet werden. Der Inspektions- und Wartungszyklus berücksichtigt eine Reihe von Faktoren, einschließlich der erforderlichen Lastzyklen und Umwelteinflüsse. Die Techniker*innen von Teufelberger-Redaelli stehen Ihnen 365 Tage im Jahr zur Verfügung, um Sie hierbei zu unterstützen.

Basierend auf jahrzehntelanger Erfahrung auf dem Gebiet der Seilsysteme geht das Angebot von Teufelberger-Redaelli über die Konstruktion, Herstellung, Lieferung und den Vertrieb hinaus. Es ist von entscheidender Bedeutung, dass die Installation und das Spannen von Seilen auf sichere und gut geplante Weise erfolgt.

Das Team von Teufelberger-Redaelli besteht aus erfahrenen Ingenieur*innen, die über die notwendigen technischen Ressourcen verfügen, um ein komplettes Paket anbieten zu können. Von der Unterstützung und Beratung im Vorfeld des Entwurfs über die Konstruktion, dem Spannen sowie der Inspektion bis hin zur Wartung können Sie sich darauf verlassen, dass Teufelberger-Redaelli einen ganzheitlichen Ansatz bietet, um all diese wichtigen Aktivitäten in einem Paket zu vereinen

MONTAGE UND SPANNEN

Die korrekte Montage, Installation und Spannen der Seile auf der Baustelle ist von entscheidender Bedeutung Dadurch gewährleisten wir, dass die Seile sicher, pünktlich innerhalb des Budgets und gemäß den Spezifikationen installiert werden.

Teufelberger-Redaelli ist bestrebt, sich in der frühestmöglichen Phase des Projektentwurfs einzubringen, um sicherzustellen, dass alle Optionen und Einschränkungen berücksichtigt werden. Aufgrund unserer langjährigen Erfahrung gibt es oft mehrere verschiedene Installations- und Spannoptionen, die untersucht und letztendlich eingesetzt werden können.

Die Zusammenarbeit mit dem Ingenieursteam von Teufelberger-Redaelli während der Planungsphase bedeutet einen kooperativen Ansatz mit dem Planungs- und den Bauteams, um die Erfüllung des Kundenprojekts zu gewährleisten und kostspielige Fehler und Nachbesserungsarbeiten zu vermeiden.

Teufelberger-Redaelli bietet unter anderem folgende Spezialgebiete an:

• Konstruktionsunterstützung für das -Seilsystem.

• Installationsoptionen einschließlich der Anordnung der Komponenten vor Ort und Vormontagepläne.

• Vormontage von Seilverbindungen und aller Anbauteile, einschließlich Klemmen und Abstandshalter.

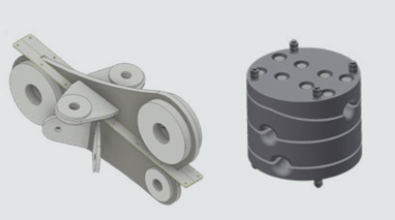

• Spezifizierung, Planung und Mobilisierung von Seilspannvorrichtungen.

• Unterstützung bei der Planung von Baustellenaktivitäten im Zusammenhang mit der Seilinstallation.

• Unterstützung bei der Wahl der Spannreihenfolge und der Spannstufen.

• Spannen von Seilverbindungen, einzeln, paarweise, gruppenweise oder in komplexen synchronisierten Aufzugsprogrammen.

• Endkontrolle der Seilkräfte mit abschließendem Spannprotokoll.

• Unterstützung bei der Anbringung von Seilzubehör, z. B. einschließlich der Aufbringung von Teufelberger-Redaelli Tensocoat, einem Seilkorrosionsschutz, auf die Seiloberflächen und anderen zugelassenen Anstrichsystemen.

• Unterstützung bei der Demobilisierung von Personal, Ausrüstung und Verpackung.

• Planung, Mobilisierung und Durchführung von Entspannungsarbeiten von Seilkonfektionen und -netzen in bestehenden Konstruktionen.

PRODUKTANPASSUNG

Teufelberger-Redaelli entwirft und fertigt Anbauteile für das Seil nach den jeweiligen projektspezifischen Anforderungen.

Teufelberger-Redaelli plant und produziert Anbauteile für das Seil nach den jeweiligen projektspezifischen Anforderungen. Zudem wird in Zusammenarbeit mit unseren Kunden für spezifische Anwendungen eine individuelle Lösung entwickelt.

Teufelberger-Redaelli hilft regelmäßig bei der Entwicklung, Herstellung und Installation von verschiedenen Seilklemmen, um der Anwendung der Struktur gerecht zu werden. Die Entwürfe hierfür werden in Übereinstimmung mit internationalen Normen wie EN 1993-1-11, EN 1993-1-1 und EN 1993-1-8 erstellt und ausgeführt.

WARTUNG

Regelmäßige, sorgfältig geplante Wartungsarbeiten sind unerlässlich, um die langfristige Gesundheit von seilgestützten Strukturen zugewährleisten. Die Planung und Durchführung dieser Seilwartungsarbeiten ist ein wichtiger Kernbestandteil des Serviceangebots von Teufelberger-Redaelli.

Je nach Art des Bauwerks, den Umgebungsbedingungen sowie der Zugänglichkeit des Geländes kann ein Seilwartungsplan erstellt werden, der einen detaillierten Überblick über die verschiedenen Lebensdauerphase des Bauwerks und die damit verbundenen empfohlenen Maßnahmen und Unterstützungsleistungen bietet.

Je nach Lebensdauerphase sind verschiedene Arten von Kontrollen und Maßnahmen erforderlich, darunter:

• Grundlegende visuelle Beobachtung, um sicherzustellen, dass alle Elemente der Seilbaugruppe, z. B. Seile, Muffen und alle Zusatzteile eine gleichmäßige Geometrie und Seilkräfte aufweisen.

• Grundlegende visuelle Beobachtung, um sicherzustellen, dass alle Elemente der Seilbaugruppe, z. B. Seile, Muffen und alle Zusatzteile eine gleichmäßige Geometrie und Seilkräfte aufweisen.

• Einfache Inspektion, um den Zustand der Oberfläche und der äußeren Drähte sowie den Zustand des Korrosionsschutzes zu beurteilen. Diese umfasst die Messung der Dicke der Schutzschichten der Seilsysteme und die Überprüfung der -Hülse, Kegel und Passung. Sie kann auch die Demontage, den Ausbau und den Austausch der Korrosionsschutzsysteme der Seile umfassen und erfordert unter Umständen einen speziellen Zugang zu den einzelnen zu prüfenden Seilkomponenten.

• Hauptinspektion: Umfassende Tätigkeiten, die in der Regel zusätzlich zu den visuellen und einfachen Inspektionstätigkeiten durchgeführt werden.Diese umfassen erweiterte Instrumentenkontrollen zur Messung der Seilkraft, um die Dauerhaftigkeit des Vorspannungszustands zu überprüfen Des Weiteren auch das Nachspannen von Seilen, um die Effizienz der Struktur zu gewährleisten, eine geometrische topografische Vermessung, die Demontage oder das Entfernen und Ersetzen von Korrosionsschutzsystemen oder Seilkomponenten sowie einen speziellen Zugang zu jeder der Seilkomponenten der strukturellen Seilanlage.

Weitere Inspektions- und Wartungstätigkeiten können projektspezifisch festgelegt werden.